| Company | Ingredient Name | ID | Comments | Naturality | Certifications | Purity | Latin name | Treated part | Geographical origin | MOQ |

|---|---|---|---|---|---|---|---|---|---|---|

|

|

Huile essentielle d'Opoponax - 30 gr | - |

Visit website

|

- | - | - | - | - | - | |

|

|

OPOPONAX Essential Oil | M_0020100 |

Visit website

|

Naturel | - | - | - | - | - | |

|

|

OPOPONAX Rectified Essential Oil | M_0052405 |

Visit website

|

Naturel | - | - | - | - | - | |

|

|

OPOPONAX | F1828 |

Visit website

|

Huile essentielle |

|

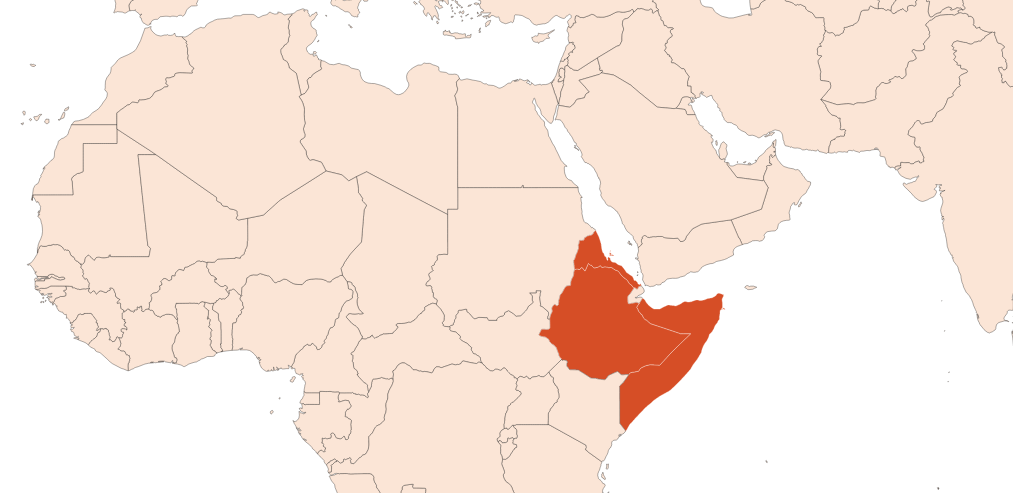

- | Commiphora erythraea(Ehrenb.) Engl. | Exsudat | Somalie | - |

General Presentation

-

CAS N° : 8021-36-1

-

EINECS number : 639-660-5

-

FEMA number : Donnée indisponible.

-

Appearance : Yellow to dark yellow liquid

-

Density : 0,880 - 0,912 @20°C

-

Volatility : Heart

-

Price Range : €€€€€

Physico-chemical properties

-

Optical rotation : Donnée indisponible

-

Vapor pressure : Donnée indisponible

-

Refractive Index @20°C : Donnée indisponible

-

Acid Value :

-

Flash Point :

Uses

Uses in perfumery :

Used over all in woody, spicy and incense notes and in oriental perfumes to bring a spicy-woody and natural effect.

Major Components :

- Elemene

- Capene

- Sesquiterpenes and furanic sesquiterpenones

Photo credits: ScenTree SAS

Botanical name :

Data not available.

Botanical profile :

Opoponax is the resin of a tree of the Burseraceae family and the genus Commiphora.

Chemotypes :

The genus Commiphora regroups 190 species. In perfumery, Commiphora myrrha is also cultivated, and corresponds to myrrh resinoid or myrrh EO, also grown in East Africa but with a spicier and reminiscent smell of plastic.

Extraction process :

As for myrrh, the resin secretion of the opoponax tree is provoked to let the resin tears flow down the bark of the tree. Once dry, these tears are collected with a blade and freed from their impurities by filtration. After that, they are exported to Europe to be extracted.

An essential oil and a resinoid can be obtained. The essential oil is obtained by steam distillation of the resin, under high pressure. Aromatic compounds are brought to a condensor, to settle the essential oil in a florentine flask, over water.

Opoponax Resinoid is obtained by diluting the tree resin in cold alcohol and after filtration and evaporation of the solvent. It is also possible to obtain a supercritical CO2 extract of myrrh with a superior olfactory quality.

The resinoid may be bleached by distillation.

Other comments :

Originally, opoponax was one of the resins that were burned for the gods because the fumigations are smellious and considered as an offering in this regard.

Stability :

The terpenes identified in this raw material can polymerize when they are oxidized

Regulations & IFRA

Allergens :

Cinnamates

IFRA 51th :

This ingredient is restricted by the 51th amendment

- Quantitative limit on the use :

-

Cat.1 Cat.2 Cat.3 Cat.4 Cat.5A B C DCat.6 0,077 % 0,023 % 0,46 % 0,43 % 0,11 % 0,11 % 0,11 % 0,11 %0,25 % Cat.5A B C DCat.6 0,11 % 0,11 % 0,11 % 0,11 %0,25 % Cat.7A BCat.8 Cat.9 Cat.10A BCat.11A BCat.12 0,88 % 0,88 %0,045 % 0,84 % 3 % 3 %1,7 % 1,7 %No Restriction Cat.10A BCat.11A BCat.12 3 % 3 %1,7 % 1,7 %No Restriction

-

Specified ingredients: notes

Opoponax oil can be obtained from solvent extraction or pyrolysis. Opoponax oil obtained through pyrolysis shall be rectified according to Good Manufacturing Practices (GMP) and the content of Polycyclic Aromatic Hydrocarbons (PAH) resulting from their use shall respect the following requirement: Benzopyrene and 1,2-Benzanthracene are to be used as markers for PAH. If used alone or in combination with rectified Cade oil, rectified Birch tar oils or rectified Styrax oil, the total concentration of both of the markers should not exceed 1 ppb in the final product.